Saudi Arabia’s construction sector is evolving at an unprecedented pace, driven by Vision 2030, major infrastructure projects, and real estate developments. As timelines shrink and project complexity grows, effective supply chain management in construction has become a decisive factor in meeting delivery schedules and maintaining profitability.

Unlike traditional industries, the supply chain in the construction industry is fragmented. Materials are sourced from multiple regions, deliveries are site-specific, and procurement must align with project progress.

That’s where ERP for supply chain management in construction makes a difference. It enables real-time visibility and control across every stage, from supplier purchase orders to material delivery on-site. For Saudi contractors, this integration ensures that supply operations stay compliant with ZATCA and SOCPA regulations while improving efficiency and cash flow.

In this article, we’ll explore how ERP supports construction purchasing and supply chain management, covering its key benefits, essential features, and practical strategies to help Saudi construction companies achieve transparency, cost control, and long-term operational resilience.

What is ERP for Supply Chain in Construction Industry

Every supply chain in construction is highly variable, as materials come from different suppliers, project timelines shift, and deliveries must align precisely with on-site progress. Unlike manufacturing, there’s no fixed production line; every project is unique. This makes it essential for companies to use systems that bring structure, visibility, and control to constantly changing workflows.

As reported by Dimension Market Research, Saudi Arabia’s supply chain sector accounts for nearly 7% of the national GDP (2023), reflecting how integral efficient logistics and material movement are to the country’s construction-driven economy[?].

An ERP designed for the supply chain in construction industry centralizes procurement, inventory, logistics, and financial data into one unified system. It allows project teams, procurement officers, and suppliers to operate from the same source of truth, ensuring materials are available when and where they’re needed.

This integration is what differentiates generic ERP platforms from construction-specific ones; the latter are purpose-built to handle project-based operations, equipment tracking, and multi-site coordination that define modern construction supply chains.

Specifics of Construction ERP vs Generic ERP

Generic ERPs cover standard functions (finance, HR, basic procurement). Construction projects, however, run across multiple sites, rely on shifting specifications, and depend on tight coordination between field teams, suppliers, and equipment fleets. That complexity demands a system built for supply chain management in construction.

Large construction projects take 20% longer to complete than planned and exceed their original budgets by up to 80%, largely due to poor coordination across procurement, logistics, and on-site operations, inefficiencies that specialized ERP systems are designed to eliminate[?].

A construction-focused ERP embeds project workflows like job costing, contract/variation control, and progress billing, so every PO, GRN, and site issuance maps to a project activity. That’s essential for supply chain management in ERP, where purchasing, deliveries, and cost capture must align with milestones.

It also handles equipment and asset management utilization, maintenance, and downtime, so plant availability is planned alongside material drops. This protects schedules and reduces idle costs within the supply chain in construction industry.

Finally, construction ERP natively supports multi-site/field operations: central warehouse to multiple projects, real-time site receipts, and mobile confirmations. The result is cleaner construction purchasing and supply chain management with fewer handoffs and faster, verifiable data into the ledger.

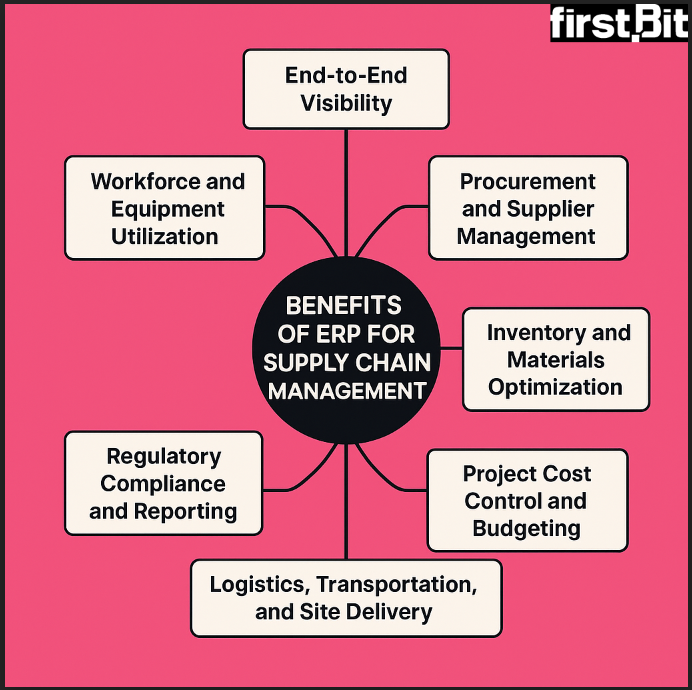

Benefits of ERP for Supply Chain Management in Construction

Benefits of ERP in supply chain management

For Saudi contractors, optimizing the supply chain in the construction industry is not just about saving costs; it’s about maintaining control over delivery schedules and avoiding project disruptions.

Construction projects rely on thousands of interconnected activities, and without centralized coordination, even a minor delay in procurement or logistics can derail timelines. An ERP system for supply chain management in construction bridges these gaps by providing real-time visibility, automation, and control across every stage of the project.

A KPMG global report found that 70% of organizations describe their supply chains as “very” or “extremely” complex, highlighting why construction companies need integrated ERP systems to manage procurement, inventory, and logistics efficiently[?].

By consolidating procurement, inventory, logistics, and financial workflows, ERP systems ensure that every transaction, whether issuing a purchase order or receiving materials on-site, is based on live project data. This creates end-to-end visibility and better cost control across the supply chain in construction industry.

For companies handling multiple sites or mega-projects in Saudi Arabia, such integration supports compliance with local regulations while strengthening cash flow and supplier relationships. ERP thus becomes more than a back-office tool; it acts as the digital backbone of construction purchasing and supply chain management.

End-to-End Visibility and Transparency

ERP eliminates data silos by consolidating procurement, inventory, logistics, and finance into one connected system. This gives contractors the real-time insights needed to make confident, data-driven decisions.

How it transforms operations:

Unified dashboards. All purchase orders, goods receipts, and stock movements are visible across departments.

Real-time material tracking. Teams can monitor each shipment from supplier dispatch to site delivery.

Single source of truth. Everyone from procurement to project management works on the same data set, reducing errors and duplication.

Predictive visibility. Early alerts flag potential material shortages before they delay the schedule.

This level of transparency allows project teams to anticipate rather than react, turning visibility into control.

Procurement and Supplier Management

A strong

procurement process anchors successful supply chain management in construction. ERP centralizes supplier data, purchase workflows, and performance insights to help contractors source materials efficiently and strategically.

Key improvements include:

Automated purchase workflows that eliminate delays caused by manual approvals.

Centralized vendor profiles with pricing history, certifications, and reliability data.

Supplier scorecards that evaluate performance on delivery timeliness and quality.

Smart sourcing alternatives that ensure supply continuity in case of disruptions.

With ERP, procurement teams no longer chase paperwork or emails. Instead, they work strategically, comparing suppliers, enforcing standards, and securing better pricing based on verifiable data.

Inventory and Materials Optimization

For contractors, material management directly impacts cash flow and productivity. ERP gives real-time visibility into stock levels, allowing teams to maintain just enough inventory to meet demand without tying up capital.

Core advantages:

Automated stock updates after every purchase or site issuance.

Dynamic reorder points that trigger alerts before shortages occur.

Forecasting tools that balance just-in-time delivery with safety stock requirements.

Cross-site visibility showing where materials can be reallocated or shared between projects.

By aligning material availability with construction schedules, ERP ensures resources are always where they’re needed, minimizing waste, transport costs, and idle time.

Project Cost Control and Budgeting

Cost overruns in the supply chain in construction industry usually stem from poor coordination between procurement, delivery, and finance. ERP closes this gap by integrating all cost-related data in real time.

This integration enables:

Live budget monitoring. Each purchase, delivery, or payment is tied to a specific cost center.

Variance analysis. Project teams can instantly compare planned and actual costs.

Forecasting accuracy. Early warnings help managers prevent overruns before they escalate.

Actionable insights. Financial dashboards connect material consumption and cost performance.

This end-to-end financial visibility ensures that every riyal spent contributes directly to project progress and profitability.

Logistics, Transportation, and Site Delivery

In large construction projects, logistics determines whether a schedule succeeds or stalls. ERP brings visibility and structure to this often-overlooked part of the supply chain management in the ERP ecosystem.

The difference ERP makes:

Route planning and optimization reduce fuel consumption and transport delays.

Live tracking keeps teams informed of where each shipment is at any moment.

Customs and import modules ensure smooth clearance for imported materials.

Warehouse-to-site synchronization prevents idle time and double deliveries.

With logistics fully integrated into the ERP system, materials flow seamlessly from storage to the site, ensuring that field operations stay on schedule and within budget.

Regulatory Compliance and Reporting

Saudi contractors must meet strict ZATCA, SOCPA, and VAT requirements while maintaining internal controls. ERP embeds these standards into everyday workflows, turning compliance from a burden into a built-in advantage.

Compliance becomes effortless with:

ZATCA-compliant e-invoicing through the Fatoorah system, with Arabic language support.

Automatic VAT calculation and posting at each transaction stage.

Digital audit trails capturing supplier invoices, approvals, and delivery documents.

Instant reporting to government portals or internal stakeholders.

These features ensure every financial and supply transaction is accurate, transparent, and fully traceable, protecting companies from penalties while strengthening operational accountability.

Workforce and Equipment Utilization

Construction projects depend on how effectively materials, labor, and machinery work together. ERP connects these components so that resource planning becomes proactive rather than reactive.

Operational advantages include:

Integrated scheduling that links equipment and crew availability to delivery timelines.

Preventive maintenance tracking that reduces downtime and extends machinery lifespan.

Utilization analytics reveal underused assets or overburdened teams.

Dynamic reallocation of resources across multiple projects for maximum efficiency.

When labor, equipment, and materials are managed within one system, projects run smoothly, deadlines are met, and productivity increases, forming the foundation of efficient construction purchasing and supply chain management.

Key Features for Supply Chain Management in ERP

Modern ERP in supply chain management integrates the tools for procurement, logistics, inventory, and finance into one unified ecosystem. For construction companies, these features ensure that material movement, costs, and compliance remain synchronized no matter how many sites or subcontractors are involved.

1. Project and Contract Management

Construction supply chains revolve around projects, not products. ERP systems are built to handle project-specific workflows that tie together contracts, budgets, and delivery timelines.

Scheduling and milestone tracking help project teams align procurement and material requirements with construction phases.

Change order and variation control ensure all contract modifications are documented and cost before approval.

Integrated documentation keeps every contract version, drawing, and supplier term accessible in one place.

Procurement linkage connects material requests directly to project milestones, ensuring supplies are available when each phase begins.

This structure makes project execution smoother and helps companies maintain accountability at every level, from planning to post-delivery.

2. Procurement and Supplier Management

ERP centralizes every procurement activity, ensuring that sourcing decisions align with project needs and budgets.

Automated purchase order workflows eliminate paperwork and reduce processing time.

Requisition approval routing maintains cost control and prevents unauthorized spending.

Vendor dashboards and scorecards track supplier reliability, pricing consistency, and on-time performance.

Contract and supplier history create a database of verified vendors for future projects.

The result is an agile procurement function where teams spend less time chasing approvals and more time managing supplier performance and cost efficiency.

3. Inventory, Materials, and Warehouse Management

ERP makes inventory management precise and data-driven, a necessity in large projects where materials move through multiple storage points.

Real-time stock monitoring shows what’s available, reserved, or in transit across all sites.

Material requisition and issuance logs link every delivery to a specific project or phase.

Automated reorder points and safety stock rules prevent both excess inventory and shortages.

Multi-site visibility enables inter-project material transfers, reducing unnecessary purchases.

This automation keeps warehouses organized, improves cash flow, and ensures no material sits unused or goes missing.

4. Logistics and Transport Module

Construction logistics involves coordinating deliveries across long distances and tight schedules. ERP integrates transport management with procurement and inventory data to make logistics predictable and transparent.

Route optimization minimizes delays and fuel costs.

Real-time shipment tracking provides visibility from dispatch to the site.

Inbound and outbound coordination ensures materials arrive as planned, reducing idle equipment and labor.

Customs and 3PL integration streamline import workflows and reduce paperwork for international shipments.

By linking logistics with the rest of the supply chain, ERP turns transportation into a controlled, data-backed process that supports timely project execution.

5. Cost Control, Job Costing, and Financial Integration

One of ERP’s strongest capabilities is the ability to connect physical supply movement with financial outcomes.

Real-time cost tracking ties every material, labor, or equipment expense to a project cost center.

Variance analysis and forecasting help identify potential overruns before they impact margins.

Integrated general ledger and accounts payable ensure that each transaction is reflected in the company's books instantly.

Job costing analytics measure profitability per project, supplier, or resource category.

This financial linkage helps contractors understand where money is going, enabling better decisions and higher profit predictability.

6. Compliance, Reporting, and Audit Trail

ERP ensures that every supply chain transaction complies with Saudi Arabia’s legal and regulatory frameworks.

ZATCA-compliant invoicing with QR codes, Arabic language support, and Fatoorah integration.

SOCPA-aligned financial reporting for transparent accounting and audit readiness.

Environmental and safety compliance modules for material certifications and documentation.

Complete digital audit trails that show who approved, received, or modified each transaction.

These features safeguard against compliance risks and simplify audits, reducing manual documentation effort while maintaining transparency.

7. Resource and Equipment Management

Equipment and workforce utilization are integral to supply chain efficiency. ERP helps companies allocate and monitor resources across multiple projects.

Asset allocation dashboards track machinery and tool usage across locations.

Maintenance scheduling minimizes downtime and unexpected repair costs.

Utilization analytics reveal underused equipment that can be reassigned.

Integration with project timelines ensures resources are available exactly when needed.

When resources are managed proactively, companies reduce idle costs and improve project turnaround time, strengthening overall operational efficiency.

8. Integration with Field or Mobile App

Construction sites often face limited connectivity and delayed reporting. ERP mobile extensions close that gap by linking on-site activities directly to the central system.

Mobile receipt logging for materials and equipment ensures instant updates.

Offline data capture keeps field teams productive even in low-signal areas.

Automatic synchronization uploads site data once connectivity is restored.

On-site stock checks and issue requests make operations faster and more transparent.

By bridging the field and back office, ERP ensures that the supply chain remains accurate, up-to-date, and fully traceable even across remote project sites.

Tips on How To Use ERP for Construction Purchasing and Supply Chain Management

An ERP system is only effective when it’s aligned with the workflows of supply chain management in construction. When it’s done right, it helps improve purchasing accuracy, supplier collaboration, and project delivery.

These tips demonstrate how companies can derive practical value from their ERP in supply chain management:

- Define a clear procurement strategy aligned with projects. Before setting up ERP workflows, companies need to map material requirements for each project phase, define approval hierarchies, and identify supplier lead times. This clarity ensures that ERP automation aligns with on-site realities rather than generic purchasing cycles.

- Integrate procurement with inventory and supply chain modules. When these functions are linked, the system automatically checks available quantities, delivery timelines, and supplier performance before generating a new order. Lack of visibility into existing inventory can lead to duplicate orders and unused materials.

- Automate approval workflows. Manual approval chains often slow down procurement in construction. ERP systems streamline this process through automated approval hierarchies. The system automatically routes each purchase requisition or invoice to the right level of authorization based on project value, department, or vendor risk.

- Start supplier collaboration and performance tracking. ERP systems onboard vendors into a shared digital environment with centralized communication and document exchange. Afterward, suppliers can receive purchase orders directly through the ERP, confirm delivery timelines, and upload invoices or shipping documents in real time.

- Use segmentation and priority approaches for materials. Segment materials based on importance, cost, and availability. This ensures that critical materials receive faster attention while lower-priority items follow standard purchasing workflows. ERP systems support this through ABC segmentation or similar categorization methods.

- Enforce traceability, compliance, and auditability. ERP systems maintain a complete audit trail for every transaction in the supply chain management in construction process. Every purchase order, goods receipt, delivery note, and supplier invoice is automatically recorded, time-stamped, and linked to the relevant project.

- Aim for continuous improvement and feedback. Regularly review procurement and supply chain data to identify inefficiencies and refine their ERP workflows. Organize regular feedback sessions between teams. Use these insights to adjust reorder points, modify approval hierarchies, or improve supplier selection criteria.

- Implement change management. Successful implementation starts with communication and training. Teams should understand how ERP simplifies their daily tasks and be involved in the configuration to ensure the system reflects real processes. Designate “super users” or champions within each department to encourage wider adoption.

However, effective supply chain management in construction is impossible without the right industry-specific ERP software. This is where FirstBit ERP comes into play.

How FirstBit ERP Transforms Supply Chain Management in Construction

FirstBit ERP provides construction companies with an integrated platform that connects purchasing, inventory, logistics, project costing, and accounting, ensuring full visibility across every phase of the supply chain.

Each module is designed to address the real operational challenges faced by contractors in Saudi Arabia, from ZATCA compliance to multi-site coordination.

Centralized Procurement and Vendor Management

FirstBit ERP automates the entire procurement process from material requests and purchase orders to supplier billing. All vendor data, pricing histories, and performance records are stored in one place, making it easier to evaluate suppliers and control costs.

Purchase requisitions and approvals flow electronically through predefined hierarchies.

Vendor portals allow suppliers to submit quotations, view POs, and confirm deliveries online.

Purchase analytics help compare vendor prices and lead times across multiple projects.

This level of transparency ensures that purchasing decisions are data-driven, reducing delays and repetitive administrative work.

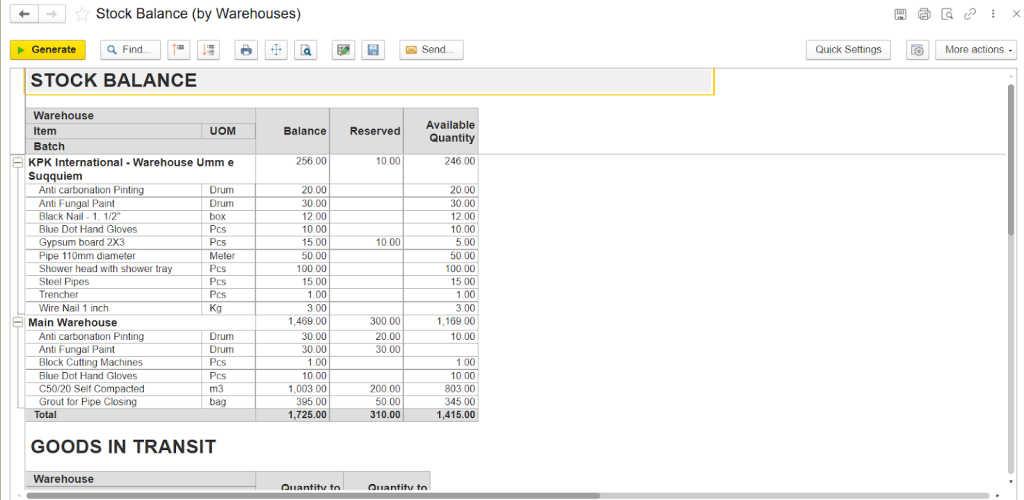

Real-Time Inventory and Material Tracking

The system gives contractors complete control over materials across

warehouses and project sites. Quantities, reserved stock, and in-transit items are visible in real time, ensuring accurate planning and preventing duplication.

Material issuance and returns are linked directly to project cost centers.

Automated reorder levels and notifications help prevent stockouts.

Multi-site inventory visibility enables the transfer of materials between projects.

These features allow companies to maintain just-right stock levels and improve overall material utilization efficiency.

Stock balance report by warehouses in Firstbit ERP

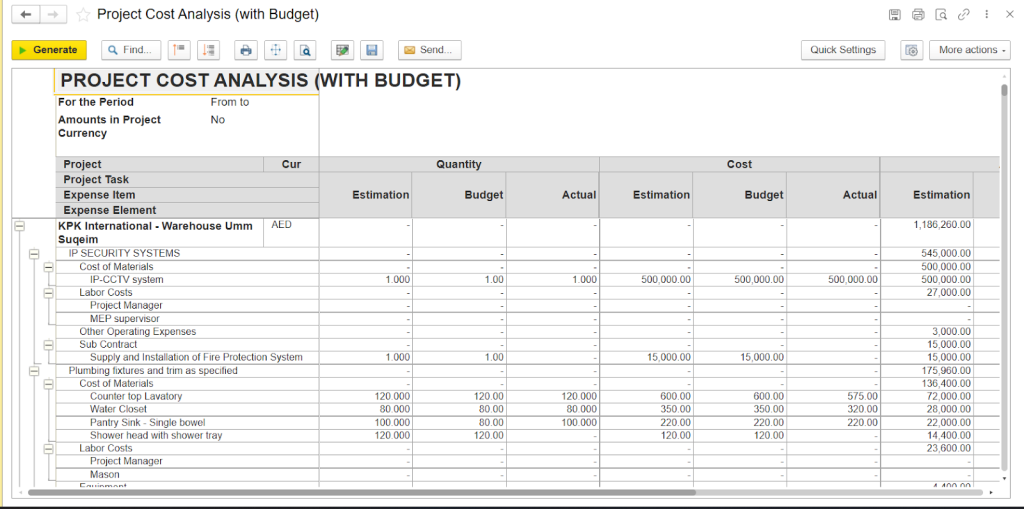

Project Costing and Budget Integration

FirstBit ERP links material and procurement costs directly to each project’s financial records, ensuring that every expense is traceable and reflected in the project budget.

Each PO, GRN, and supplier invoice automatically posts to the relevant project ledger.

Budget dashboards show planned vs. actual spending in real time.

Detailed cost reports help track profitability across phases or cost categories.

This integration gives management an accurate financial picture of ongoing projects and helps control overruns early.

Project cost analysis with budget report in FirstBit ERP

ZATCA-Compliant E-Invoicing and Audit Trail

The ERP is fully integrated with Saudi Arabia’s Fatoorah platform and certified by ZATCA for e-invoicing compliance. Every invoice generated meets the authority’s requirements for digital signatures, Arabic content, and QR codes.

Automatically generates and transmits compliant invoices to Fatoorah.

Maintains digital audit trails with time stamps for every transaction.

Supports VAT posting, reporting, and reconciliation for construction projects.

This ensures that companies meet national tax and documentation standards without manual processing or compliance risks.

Conclusion

As projects grow larger and supply chains become more complex, manual coordination between procurement, logistics, and accounting is no longer sustainable.

An ERP system designed for supply chain management brings all these functions together, giving companies real-time visibility, standardized workflows, and measurable accountability across every project phase.

FirstBit ERP simplifies this transformation by providing contractors with a system built around the realities of regional construction, local tax compliance, Arabic documentation, and multi-site operations. The result is a connected supply chain in the construction industry that runs with precision, transparency, and complete financial clarity.

FAQ

What is construction supply chain management, and why is it challenging in KSA?

Construction Supply Chain Management (CSCM) is the coordinated planning and control of all materials and logistics from supplier to site. In Saudi Arabia, it is challenging due to vast geography, complex regulations, reliance on imports, market volatility from giga-projects, and fragmented coordination among contractors.

How does an ERP system improve procurement in construction projects?

An ERP system streamlines construction procurement by centralizing data, automating workflows, and providing real-time visibility. This reduces manual errors, cuts processing times, enables better inventory control, and ensures accurate cost tracking against budgets, leading to significant cost savings and fewer project delays.

Can ERP help prevent material shortages or overstocking on construction sites?

Yes, ERP prevents material shortages and overstocking by providing real-time inventory visibility, accurate demand forecasting, and automated purchase tracking, ensuring optimal stock levels and reducing costs.

Umme Aimon Shabbir

Editor at First Bit

Aimon brings a deep understanding of the modern construction business to her articles. Her strength is providing practical content that enhances users’ understanding and usage of the software in the industry. As an editor, Aimon helps our authors reach their full potential and produce their best work.